Glass bottom dish, glass bottom plate, chambered cover glass FAQs

What are the thickness and material of different coverslips?

| Coverslip | Thickness (mm) | Material |

|---|---|---|

| #0 | 0.085-0.115 | Cover glass |

| #1 | 0.13-0.16 | Cover glass |

| #1.5 | 0.16-0.19 | Cover glass |

| #1.5H | 0.170±0.005 | Extremely flat high peformance cover glass |

| #1.5P | 0.175±0.01 | Tissue culture treated polymer cover slip with optical characteristics very similar to that of a cover glass. Recommended for applications where better cell attachment is desired. Not suitable for TIRF. Plates with large wells, such as the 12/24 well plates, that uses #1.5P coverslip may not be suitable for applications such as whole plate auto-scan, where whole plate flatness is critical. Because the film is soft and therefore is slightly curved within large wells. |

| #1.5Grid | 0.16-0.19 | Cover glass with a 20x26 Grid |

What are the applications each coverslip is suitable for?

+: applicable, ++: recommended, Not suitable

| #0 | #1 | #1.5 | #1.5H | #1.5P | #1.5Grid | |

| Differential Interference Contrast (DIC) | + | + | + | + | + | + |

| Widefield Fluorescence | + | + | + | + | + | + |

| Confocal Microscopy | + | + | ++ | ++ | ++ | ++ |

| Two-Photon and Multiphoton Microscopy | + | + | + | + | + | + |

| Fluorescence Recovery After Photobleaching (FRAP) | + | + | + | + | + | + |

| Förster Resonance Energy Transfer (FRET) | + | + | + | + | + | + |

| Fluorescence Lifetime Imaging Microscopy (FLIM) | + | + | + | + | + | + |

| Total Internal Reflection Fluorescence (TIRF) | + | + | + | + | + | |

| Super-Resolution Microscopy | + | + | + | ++ | + | + |

*For DIC imaging, using our glass top glass bottom dish, or glass bottom plates coupled with plate lid with cover glass is recommended.

Is the coverglass tissue culture treated?

No.

Most tissue culture vessels are made from polystyrene, which is a hydrophobic material. Most cultured cells are not able to attach to a hydrophobic surface. So plastic cell culture vessels are usually tissue culture treated with ionized air to render the surface hydrophilic to help the attachment of adherent cells.

Coverglass is hydrophilic by nature, therefore can be used for tissue culture without surface treatment. However cell attachment to coverglass is usually not as strong as to tissue culture treated polystyrene. Also our experience indicates that poly-lysine or collagen coating is less stable on coverglass than on surface treated plastics.What are the properties and applications for dishes and plates with #1.5P coverslip?

Most tissue culture dishes and plate are made from polystyrene. Polystyrene is hydrophobic by nature, it needs to be tissue culture treated (usually through a physical process using plasma) to render the surface hydrophilic to enable cell attachment.

Typical cover glass has a hydrophilic surface therefore does not require tissue culture treatment to enable cell attachment. However cells ususally attach weaker to cover glass than to tissue culture treated polystyrene dishes and plates. Our experiments show that tissue culture treatment of cover glass does not improve cell attachment.

#1.5P is a tissue culture treated polymer coverslip. It has optical characteristics very similar to that of a cover glass, but shows better attachment for cultured cells than cover glass. In our experience it also shows better attachment for coating media such as poly-lysine and collagen.

In comparison with cover glass, #1.5P has high transmittance within UV range (approximately 75% at 280nm). Therefore it is not suitable for applications where UV transparency is not desired.

Because #1.5P is a soft polymer, its flatness is slightly worse than that of a rigid cover glass. This is neglegible for plates with small wells, but may become a problem when the well size gets larger. Plates with large wells, such as 12 well and 24 well plates with #1.5P coverslip, may not be suitable for applications such as whole plate auto-scan, where whole plate flatness is critical. If you are not sure you can request a free sample before purchasing.

#1.5P coverslip is compatible with Nikon immersion oil type F, and Carl Zeiss™ Immersol™ Immersion Oil.

Overall, our products with #1.5P coverslips are recommended for applications where better cell attachment is desired.

What are the optical properties of the cover glass ?

ne (λ=546.1 nm):1.5255

nD (λ=589.3 nm):1.5230

Abbe value ve: 55

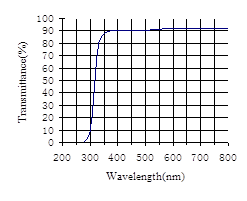

Spectral Transmittance of the #1 cover glass used for our glass bottom dish/plate:

What are optical properties of the polymer coverslip #1.5P?

Transmittance (2 mm):91.5% (400-700nm), approximately 75% at 280nm. Unlike cover glass, #1.5P is UV transparent.

Reflective index:1.53

Abbe value ve: 56

What kind of adhesive is used to adhere the dish and the cover glass? How can I detach the bottom glass?

We use a USP class VI adhesive to adhere the dish and the cover glass. This adhesive is nontoxic, and it is resistant to water and common fixing reagents such as methanol and ethanol. This makes our glass bottom dishes and glass bottom plates ideal for long term cell culture.

The adherence bond between the dish and the cover glass is quite strong, making it difficult to detach the cover glass from the dish by force.

What is the harmonized tariff code of your products?

The harmonized tariff code of our glass bottom dishes and plates is 3926.90.9910